Dow Electronic Materials

CIRCUPOSIT™ 6500 Electroless Copper Process

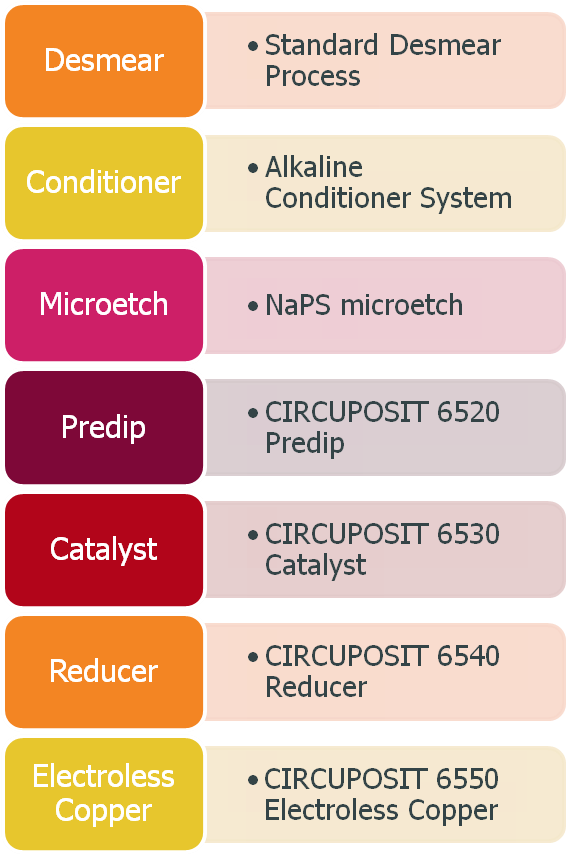

CIRCUPOSIT™ 6500 Electroless Copper Process Flow Horizontal Application

As HDI designs, especially those incorporating every layer interconnect (ELIC) technology to enable increasing functionality become more common in today’s mobile devices, tablets, and wearables, the demands on interconnect density and reliability are continuously challenged.

To meet these challenges, Dow has created the CIRCUPOSIT 6500 Horizontal Electroless Copper System, based on an Ionic Catalyst and a Tartrate-based Electroless copper for ELIC and IC Substrate applications.

Key Features of the process:

- Conditioning system, coupled with the Catalyst and Electroless copper designed for coverage on today’s advanced dielectrics.

- Horizontal process for ease of handling, uniform chemistry application, reduced operator exposure to chemicals & vapors

- Highly stable Alkaline Ionic Catalyst, with little or no sludge formation

- Tartrate-based electroless copper formulated to provide excellent throwing power, bath stability, and ease of treatment.

- Excellent copper to copper adhesion of deposit for optimum copper joint reliability.

- Can be used for MSAP product/processes with ELIC or IC substrate applications

- Meets advanced reliability requirements: HCT, Pin-Pull, Thermal Stress, Thermal Shock

Read Article

Meeting the Horizontal Electroless Copper Plating Challenge with an Ionic Palladium Catalyst Process

Download Presentation

CIRCUPOSIT 6530 Catalyst Process for Electroless Copper Metallization

Read Technical Paper

Ionic Palladium Catalyst Process for Electroless Copper Metallization

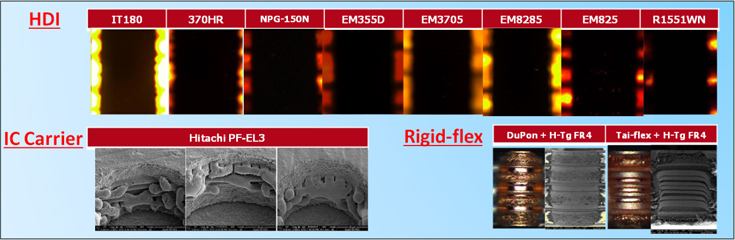

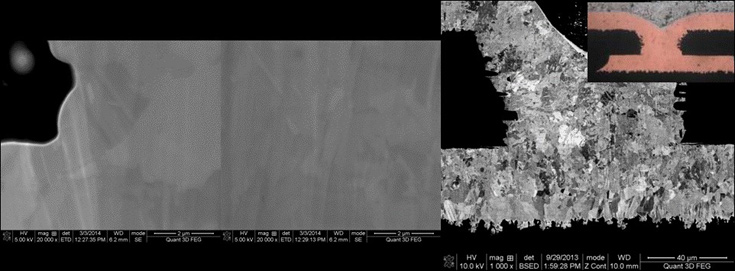

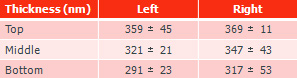

Perfect grain transfer from plated copper to target pad, with no demarcation line. Meets reliability requirements.

Full electroless Cu coverage and high throwing power in blind vias

Excellent dielectric coverage for different applications