Dow Electronic Materials

CIRCUPOSIT™ ADV 8550 Electroless Copper Process

Advanced Electroless Copper Process for Semi-Additive IC Substrate Applications, featuring an Ionic Catalyst, and a high throwing power Tartrate-base Electroless Copper, designed for adhesion to low Ra insulators.

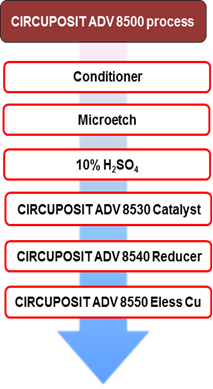

As IC packaging substrates evolve with finer features, semi-additive processing (SAP) becomes more important, requiring uniform thickness across the panel and repeatable etching characteristics. A high throw electroless copper system enables the user to have reliable coverage in microvias while minimizing surface copper deposits, thereby enhancing etching capability. Dow’s CIRCUPOSIT ADV 8500 Electroless Copper process has been developed to meet these needs.

Key Features of Dow's CIRCUPOSIT ADV 8500 Electroless Copper process:

- Alkaline Ionic Catalyst that does not require a pre-dip.

- Tartrate-based electroless copper formulated to provide excellent throwing power and bath stability.

- Excellent copper to copper adhesion of deposit for optimum copper joint reliability.

- Pure copper deposit increases etch speed; no other metal included in deposit.

- CIRCUPOSIT 7800 desmear process specifically designed for substrate insulator materials.

- Can be used for MSAP product/processes

Read Technical Paper

Next Generation Metallization Technique for IC Package Application

Excellent throwing power observed with various desmear conditions. Electroless copper thickness ~ 0.3µm.

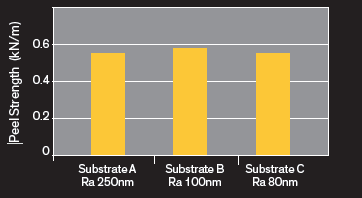

Stable adhesion on Low Ra Insulator materials