Dow Electronic Materials

SOLDERON™ BP TS 6000 Tin-Silver Plating Chemistry for

Fine-Pitch Solder - Bumping Applications

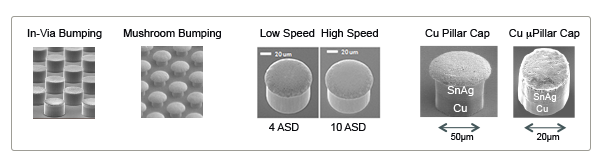

SOLDERON™ BP TS 6000 Tin-Silver plating chemistry is a high-performance lead-free alternative optimized for today's fine-pitch solder bump plating applications such as Cu pillar and micro-bumps used in 2.5D and 3D IC packaging technologies. This next-generation formulation delivers industry-leading plating rates and maximum process flexibility for flip chip packages and interconnects (Figure 1). The new chemistry features enhanced plating performance, bath stability and ease-of-use, thereby enabling the industry's widest process window with the most robust process flexibility and a competitive cost of ownership (COO).

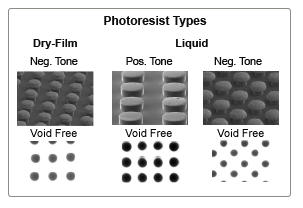

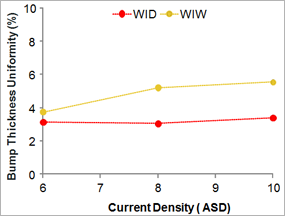

This single formulation is capable of plating speeds ranging from 2 to 9+ µm/min. The tunable nature of the Ag composition in this formulation makes it suitable for a number of applications and eliminates the need to change the chemistry to address different processing requirements. The chemistry is robust enough for both bumping and capping of a wide range of patterned wafers and it is not restricted for use with specific photoresists (Figure 2). It exhibits post-reflow with-in die (WID) bump thickness uniformity of <5% over a wide range of wafer types, which demonstrates its suitability for high-volume manufacturing (Figure 3). Additionally, it is macro- and micro-void free after reflow for improved yields and reliability (Figures 4 and 5).

SOLDERON BP TS 6000 Tin-Silver plating bath has proven to be both electrolytically and thermally stable. Offering an electrolytic bathlife of > 100 Ah/L and a ≥6-month pot life, it is compatible with in-line metrology processes, for superior ease-of-use.

Figure 1.

Examples of SOLDERON BP TS 6000 Tin-Silver's wide process

window over a range of applications, process conditions and plating rates.

Figure 2.

SOLDERON BP TS 6000 Tin-Silver exhibits consistent,

void-free performance with both dry-film and liquid photoresist.

Thickness Uniformity: Within Die (WID) and Within Wafer (WIW)

- WID Uniformity <5% from 6-10 ASD

- WIW Uniformity <10% from 6-10 ASD

Figure 3.

WID and WIW uniformity of SOLDERON BP TS 6000 Tin-Silver

demonstrates its suitability for high-volume manufacturing.

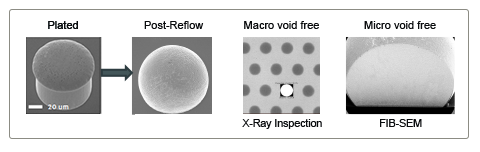

Morphology, Voiding Performance

Figure 4.

SOLDERON BP TS 6000 Tin-Silver offers improved uniformity and smoother surface

morphology in addition to a smooth, void-free interface when used together with Dow's

and other leading copper (Cu) pillar formulations.

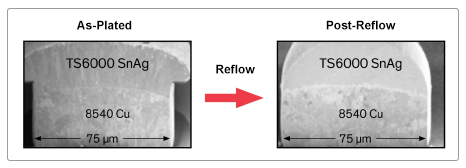

Figure 5.

In Cu pillar capping applications, SOLDERON BP TS 6000 Tin-Silver forms

a smooth, micro-void free interface post reflow.