Dow Electronic Materials

MICROFILL™ THF-100 Electrolytic Copper

|

|

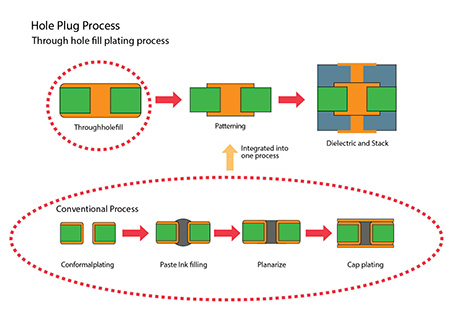

MICROFILL™ THF-100 Bath is designed to provide through hole fill of inner core layers for IC-Substrate PCB. Compared to conventional via fill processes, this new technology improves reliability, and both electrical and thermal conductivity. Customers benefit from reduced process cost and a shortened new manufacturing process.

-

Advantages:

- DC Process

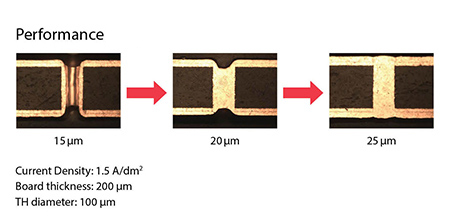

- Excellent through hole fill performance

- CVS can be applied for bath control

- Elimination of conductive paste, ink and solvents

- Highly conductive, improved thermal properties

- Excellent copper to copper adhesion, providing improved reliability

- Reduced CTE mismatch within filled via structure

- Reduced costs/Increased productivity

Download Presentation English only

Read Technical Article English only

Read Technology for Microvia Filling

MICROFILL™ LVF Electrolytic Copper