Dow Electronic Materials

MICROFILL™ EVF 15 Via Fill

Over the past several years, Dow’s MICROFILL™ EVF Via Fill has been providing enhanced microvia filling, with simultaneous through-hole plating capability, at previously unattainable surface thicknesses. A new generation of via fill, MICROFILL™ EVF15 Via Fill, has been developed to meet these requirements with a plated copper (Cu) surface thickness of 15 microns. This new electrolytic chemistry was designed to be a drop-in solution for existing vertical continuous plater (VCP) lines. The new generation EVF provides the following benefits:

- Complete fill at lower Cu thickness

- Reduced dimples and skip-rate, and,

- Improved surface appearance.

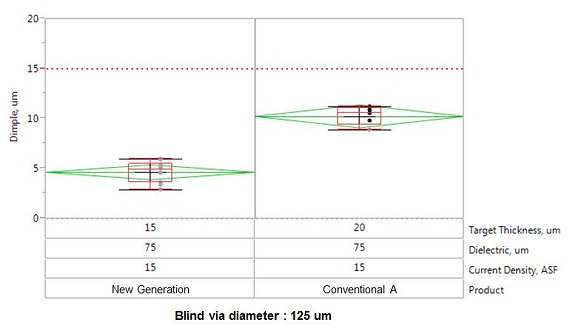

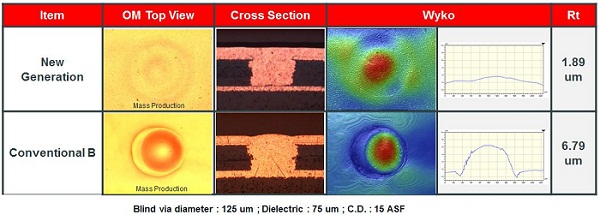

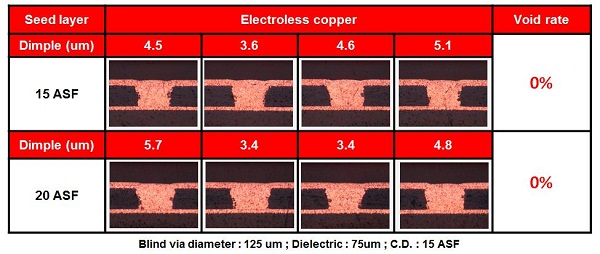

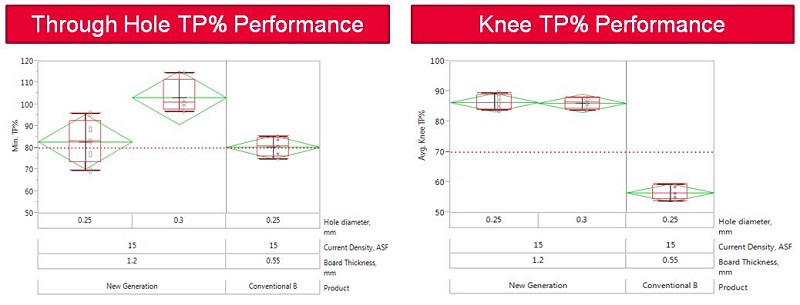

Compared to a conventional via fill process, the EVF15 provides better dimple performance at a lower plated Cu thickness (Image 1). At higher plating thicknesses, a bump may be an issue, with an excessive bump creating issues with dielectric thickness or in stacked via applications. The EVF15 performs well, exhibiting a much smaller bump as compared to a conventional process (Image 2). Filling performance as a function of plating thickness and current density also show excellent performance (Image 3 and Image 4). Looking at the knee and through-hole throwing power (TP) performance, we can see that EVF15 outperforms a conventional via fill process (Image 5).